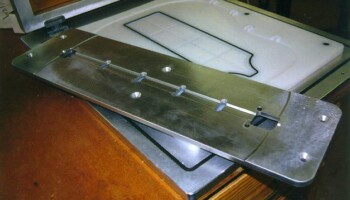

These are templates Jim has used to guide cutting of wood for guitar backs; there is one template for each body size. The wood is held to the template with a vacuum; the black strips are gaskets to seal the vacuum. The templates are oversized by 50 mil to account for later trimming. Top and back cutting is now accomplished with the laser cutter

The back is braced with a center strip and several cross braces. The metal plate seen here is a template for routing the back center strip to length and for routing clearance slots for the cross braces

A back lying on the center strip routing template. The template has curved ledges so the back fits precisely in place

Jim devised this vacuum press for gluing back and top braces in place. The white forms hold backs and braces in place as the glue sets; they are made of UHMW polyethylene machined with the Fadal. Besides the obvious slots around the edge for holding the braces, these back forms are machined with a 15 foot radius to keep the back properly curved. Just visible above the upright forms is the aluminum frame holding a thick rubber top that holds the braces against the back when the vacuum is pulled