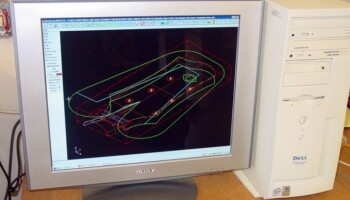

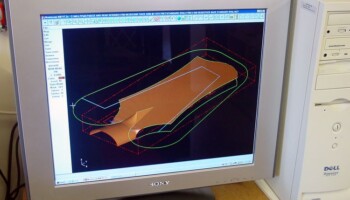

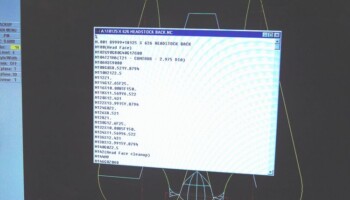

The Fadal (“fuh-DOLL”) is a computer-numerical-control (CNC) vertical machining center (VMC) manufactured by Fadal Machining Centers in Chatsworth, California. In a nutshell, the Fadal can automatically machine what ever the user draws with computer-aided-design(CAD) software. The toolpaths or machine movements ( X-Y and Z axis) are generated from the scale drawings. The operator defines the parameters for tool size, spindle speeds, and feed rates in the program and the machining code (G-code) is then generated from the drawing.

The Fadal (“fuh-DOLL”) is a computer-numerical-control (CNC) vertical machining center (VMC) manufactured by Fadal Machining Centers in Chatsworth, California. In a nutshell, the Fadal can automatically machine what ever the user draws with computer-aided-design(CAD) software. The toolpaths or machine movements ( X-Y and Z axis) are generated from the scale drawings. The operator defines the parameters for tool size, spindle speeds, and feed rates in the program and the machining code (G-code) is then generated from the drawing.

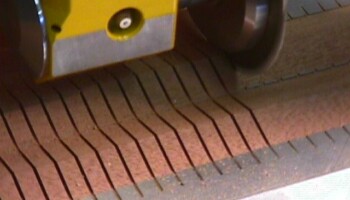

CNC machining is commonly used in large factories. Taylor guitars in particular makes heavy use of CNC machining; the new Taylor neck-body joint would not be possible without the high precision and consistency of CNC machining. A CNC machine of the sophistication of the Fadal is not a tool that you’ll find in most small shops because they are expensive (the used one that Jim bought had a final cost, including installation, tooling and software, of about $100,000). Jim was inspired to take the plunge and make the huge investment after consulting with Bob Taylor of Taylor Guitars, and Tom Anderson of Anderson Guitars, a small shop specializing in electric guitars that uses CNC machining. Even with their expert advice, and the help of a young “whiz kid” Matt Hajicek, who Jim hired part time to help him, it took many months for Jim to become productive with the Fadal. But the expense and hard work have paid off as the Fadal has helped Jim accomplish things he had only dreamed of before he had this versatile tool.

Maybe even more advantageous than making guitar parts, is the Fadal’s ability to accurately make tools and fixtures that are important to the guitar making process. This page provides an overview of how the Fadal works and some of the many tasks accomplished with this wonderful machine.

Jim had made over 800 guitars before acquiring this incredible machine. After undergoing shoulder “rotator cuff” surgery to repair damage from over use, Jim realized the need for change. Always a machine junkie, this appeared like the ultimate. When he was once consulting with his friend Bob Taylor from Taylor Guitars about making a gang saw for sawing linings, Bob said “Why would you want to spend all that time and money making a machine that will do only one thing , when you can buy a machine that can do almost everything!” The time seemed right, and Jim has never regretted the decision. These photos represent some of the fixtures that Jim has made using the Fadal. You will find other examples throughout the site.